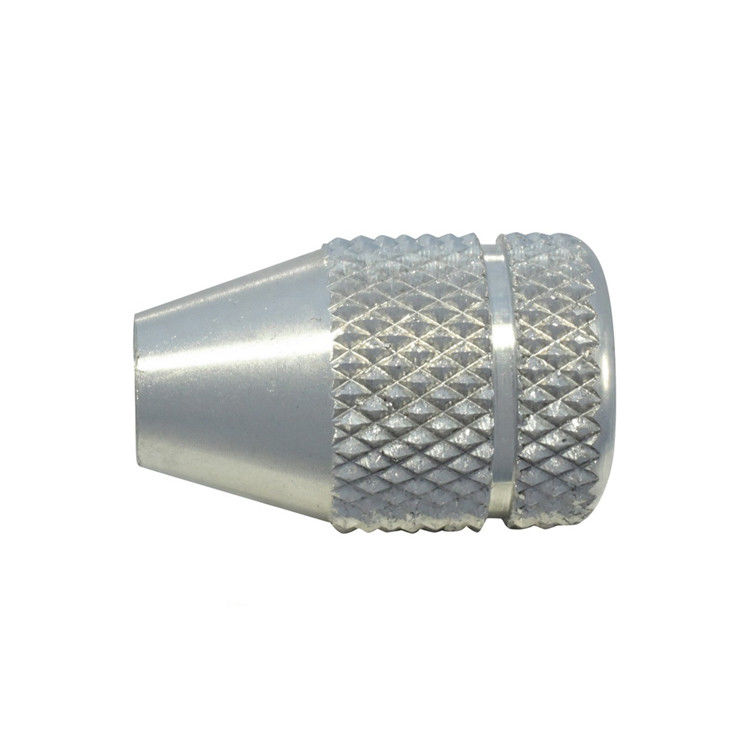

The company equipped with numerous advanced machine equipment such as CNC machining center, high speed drilling and milling machining center, CNC lathe etc., and inspection equipment including callipers, two dimensional measuring instrument, height gauge etc., but it also owns a team of professional and highly qualified mechanic talent. We have rich experience in machining stainless steel, titanium alloy, aluminum, brass parts, as well as providing all kinds of precision parts for Lithium battery equipment, medical equipment, automobile assembly equipment, liquid crystal manufacturing equipment, optical communication equipment, Optical lenses, endoscope industry etc.

Our machining scope as following:

CNC turning parts machining

CNC milling parts machining

CNC turning and milling machining

Our commonest material as following: Brass, Stainless steel, Titanium alloy, Steel, Plastic material, Aluminum, etc.

The surface finish we can supply as following:

electrogalvanizing, electroplating chromium, electroplating nickel, titanium plating, sandblasting anodizing, QPQ(Quench-Polish-Quench), Polishing, electrophoresis, etc.

1. production machine: CNC machining center, CNC engraving machine, CNC drilling center(3axis,4axis,5axis)

2. tolerance: +/-0.005mm

3. surface roughness: Ra 0.4

4. production machine origin country:China,Taiwan, Japan, Germany

Metal fabrication Processing

1. production machine: laser cutting machine,punching machine, bending machine

2. tolerance: +/-0.1mm

3. production machine origin country: China, Taiwan

Wire EDM Cutting Processing

1.production machine: WEDM-LS,WEDM-HS

2. tolerance: +/-0.003mm

4. surface roughness: Ra0.1

3. production machine origin country: China, Japan

Grinding Processing

1. production machine:surface grinder, cylindrical grinder, internal grinder

2. tolerance: +/- 0.003mm

3. surface roughness: Ra 0.025

4. production machine origin country: China, Taiwan

FAQ

A1: For the suface treatment,there are sandblasting ,anodized,plating,heat treatment ,QPQ,etc.

Q1:What the surface treatment ?

Q2: What the general anozied layer is thick?

A2:Different anodized has a different oxide layer

* Ordinary anodized 10-30um

* Hard anodized 20-40um (micron)

Q3:What type of material we can process?

A3:Stainless Steel :SS201,SS301, SS303, SS304, SS316, etc

Steel: 4140, 4340, Q235, Q345B, 20#, 45# etc

Brass:HPb63, HPb62, , HPb59, H59, H68, H80etc

Copper : C11000,C12000,C12000 C36000 etc

Aluminum : AL2024,AL6061, Al6063, AL7075, AL5052, etc

Titanium : TA1,TA2,TB1,TC4,TC18, TI GRADE2,GRADE5

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!