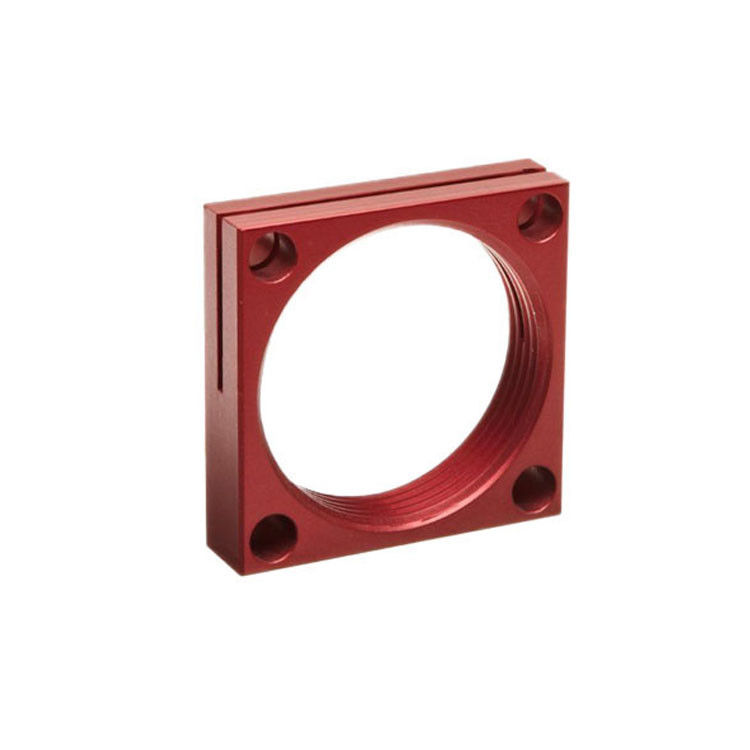

Our machining scope as following:

CNC turning parts machining

CNC milling parts machining

CNC turning and milling machining

Our commonest material as following: Brass, Stainless steel, Titanium alloy, Steel, Plastic material, Aluminum, etc.

The surface finish we can supply as following:

electrogalvanizing, electroplating chromium, electroplating nickel, titanium plating, sandblasting anodizing, QPQ(Quench-Polish-Quench), Polishing, electrophoresis, etc.

Company Information:

Tuofa factory providing comprehensive one-stop shop metal parts solutions.from design, drawing, material selection, product cost accounting, production processing and assembly, inspection, delivery, after-sales and other services.

Tuofa is one of the best manufacturers of cnc machining process in mainland China. It's main in CNC machining parts, CNC turning parts, CNC milling parts, auto lathe parts, stamping parts, Sheet metal parts.

We have invested a lot quality and production environments. In 2018, We passed the quality system review of SGS Company and got the first “ISO9001:2015” certificate. . Tuofa has carefully implemented each regulation in management details in accordance with ISO, and fully guaranteed the CNC machining product quality and customer satisfaction.

Application Area:

-- Aerospace Applications: bearing caps, connecting rods, crankshafts, cylinder heads, pistons.

-- Automotive Applications: brake calipers, brake discs, CV joint, gears, axle shaft, steering knuckles.

-- Consumer Electronics Applications: desktop computers, monitors, smartphones, vacuum chambers.

-- Energy Applications: control valves, wellhead equipment, blades and blade root, impellers.

Shipment Available:

Available are DHL, FedEx, UPS, TNT, EMS Express etc.

DHL and FedEx-IE are commonly used.

DHL: 3-4 work days to destination.

FedEx-IE: 5-7 work days to destination.

You can also choose your own forwarder.

FAQ:

1. Q: Is it possible to know how are my products going on without visiting your company?

A: Yes. We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the production process

2. Q: How can you ensure the quality?

A: We have QC department to control the quality from the beginning of production until goods finish. Quality

inspection report will be sent together with each batch goods

3. Q: If you make poor quality goods,will you refund our fund?

A: As a matter of fact, we wont take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until your satisfaction.

4. Q: What drawings format you need for production?

A: 2D, 3D both available. 2D like PDF, CAD, JPG etc. 3D like STP, IGS, STL, SAT,PRT,IPT

etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!