Excellent quality CNC machined parts as usual. Thank you Michael!

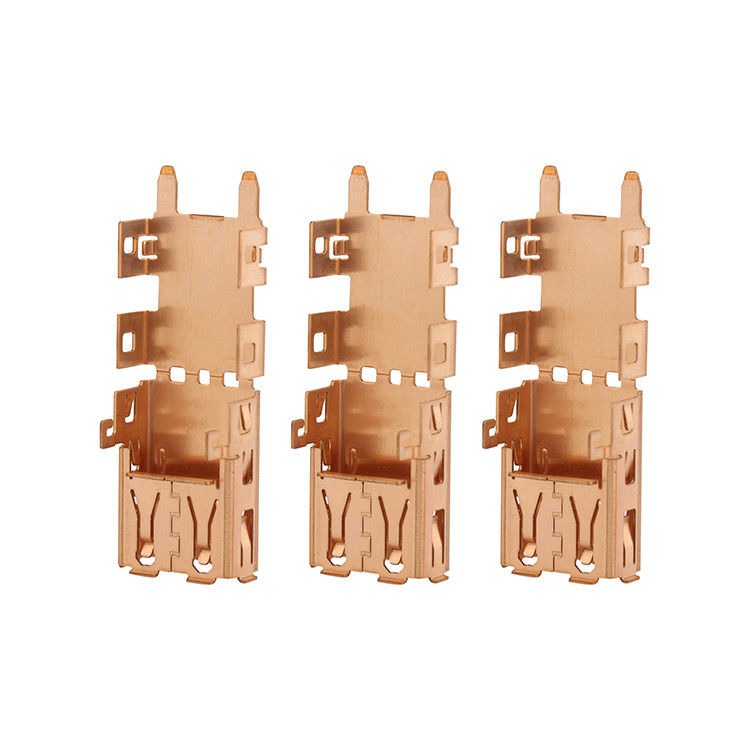

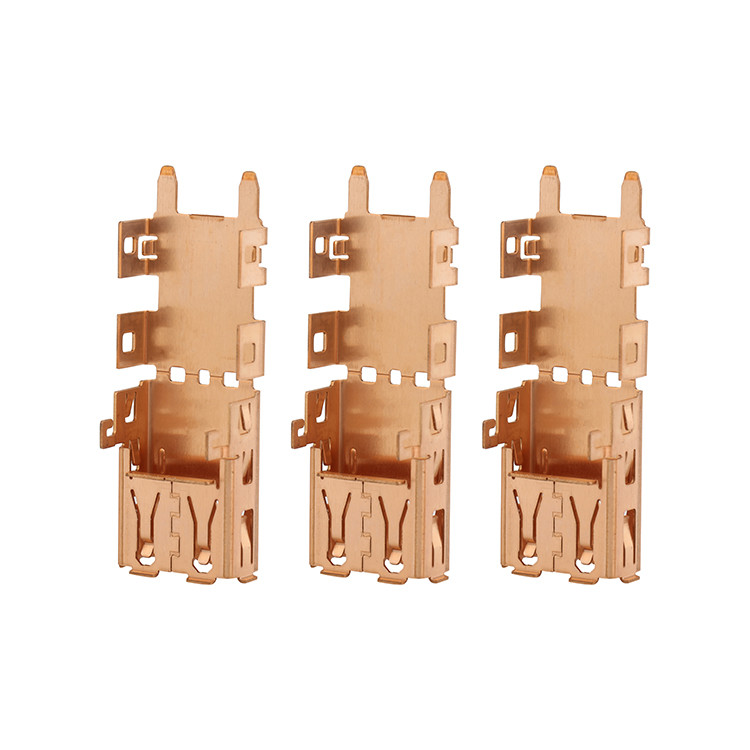

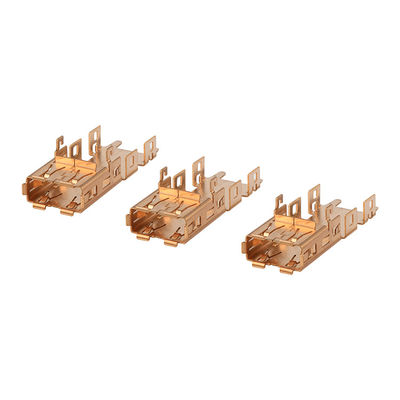

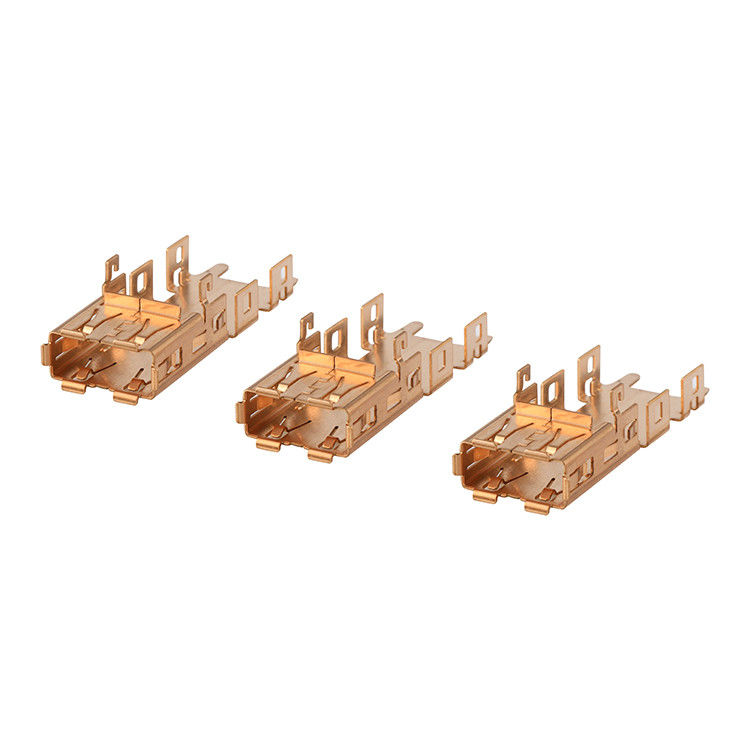

Delivered product exactly as specified in CAD CAM drawings and to all process and materials specifications.

Michael was very helpful and very professional all the way through quotation to production and she worked with me to meet our demands. The company met all our requirements and specifications and we look forward to a long working relationship.

Michael met all our requirements and specifications and we look forward to a long working relationship.

I'm quite pleased to work with Michael from Tuofa. Nice job! Expect to work together again.

We are extremely satisfied.Great customer service and response time. Very professional easy to work with Michael. Thank you again to Michael.

Very fast and professional service at an extremely competitive price. Components arrived neatly packaged and individually wrapped to ensure a blemish-free surface.

1. Good quality

Include machining, surface treatment, specification, packing, etc.

2. Proper suggestions

If you are not familiar with material, surface treatment or something, please tell us your requirement, according to which we will provide you with proper suggestions. Also, advice will be given during machining when your design is found not good enough. Anyway, it is finally up to you whether to adopt the suggestions.

3. Lower cost in machining hardended metal

We've found our way to slow the damage of tool during machining hardended metal, and as a result, the cost decreases.

4. Good after sales services

If, unexpectedly, the goods are not meet the requires, we will provide you with solutions or take yours into consideration.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!